Fuel-Air Requirements

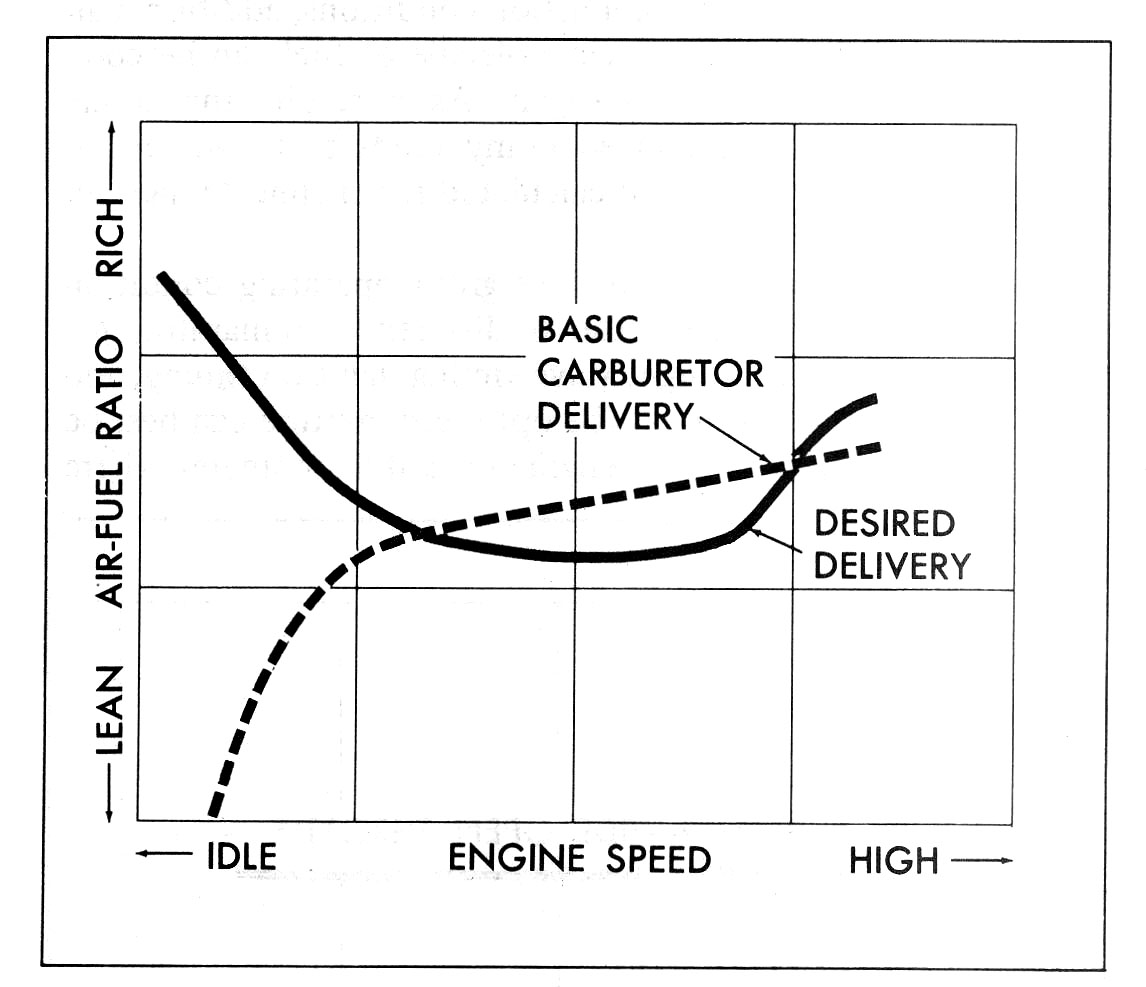

FUEL-AIR REQUIREMENTS (Fig. 10)

FUEL-AIR REQUIREMENTS (Fig. 10)

As previously mentioned, we know that without regard for efficiency, an air-fuel mixture within the range of 8-to-1 and 18 1/2-to-1 must be provided for an automobile engine to run. More practically the air-fuel ratio should be utilized which would allow peak power output, minimum emissions, and peak fuel economy. Unfortunately, no single air-fuel ratio can provide both of the above peak conditions. Tests prove the best power output is obtained using a 12.5-13.5:1 mixture whereas best fuel economy results using a 15.0-16.0:1 mixture.

Since an automobile engine must be able to provide both requirements, obviously no compromise fuel ratio would be satisfactory. Therefore a carburetor must be able to quickly match varying engine requirements with the best possible fuel mixture to meet the demand. This means that fuel ratios must be provided not only for the demand extremes of full power and peak economy but also for the interim conditions caused by light speed variations and changing engine load conditions such as a moderate grade.

One of the reasons that the air-fuel ratio must be varied is because of imperfect conditions within the combustion chamber. Exhaust gases remaining in the cylinder dilute the fresh charge. The fuel and air are not perfectly mixed, miniature droplets of unvaporized fuel being carried along by the mixture of air and evaporated fuel. The intake manifold itself does not deliver exactly equal air-fuel mixtures to all cylinders. The air-fuel ratio must therefore be adjusted, depending on such factors as engine speed and whether power or economy is desired.

Power Vs. Economy

If maximum power is desired, it is necessary to burn all the oxygen in the air, since the power-producing ability of an engine is limited by the amount of air it can take in. Additional fuel must therefore be added to insure that each molecule of oxygen combined with the necessary fuel. Thus, the mixture required for maximum power usually falls in the range from 12 to 13.5-to-1, being "richer" in gasoline than the theoretical ratio.

On the other hand, for maximum economy and least emissions, it is desirable to burn all of the fuel, in order to extract as much energy as possible with minimum residual. Because of the imperfect combustion conditions, additional air is required to insure that each molecule of fuel can be combined with the necessary oxygen. As a result, the actual air-fuel ratio for maximum economy tends to be somewhat "leaner" in gasoline than that calculated for chemically perfect combustion.

The best air-fuel ratio for any given operating condition varies from engine to engine due to differences in manifolding, combustion chamber design, valve timing, ignition timing, and other engine design factors. The optimum mixture can best be determined by operating an engine on a dynamometer where power, speed, and fuel consumption may be measured over a wide range of conditions.

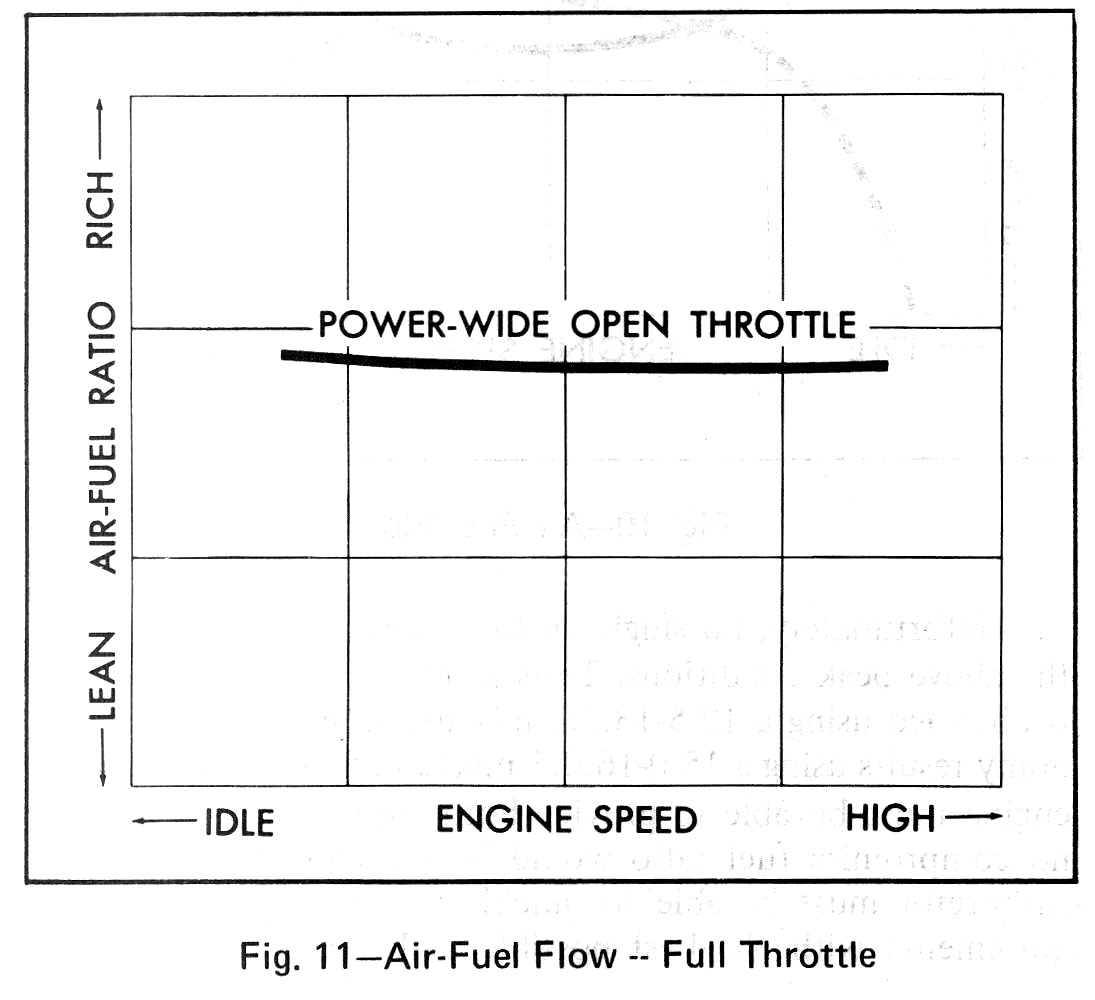

Tests made at speeds throughout the engine's operating range reveal that the air-fuel ratio for maximum power remains nearly constant at all except low speeds (Fig. 11). Here, some slight enrichment is necessary due to the effect of exhaust-gas dilution in the cylinder and the poor mixing and distribution from the lower velocity air flow into the engine.

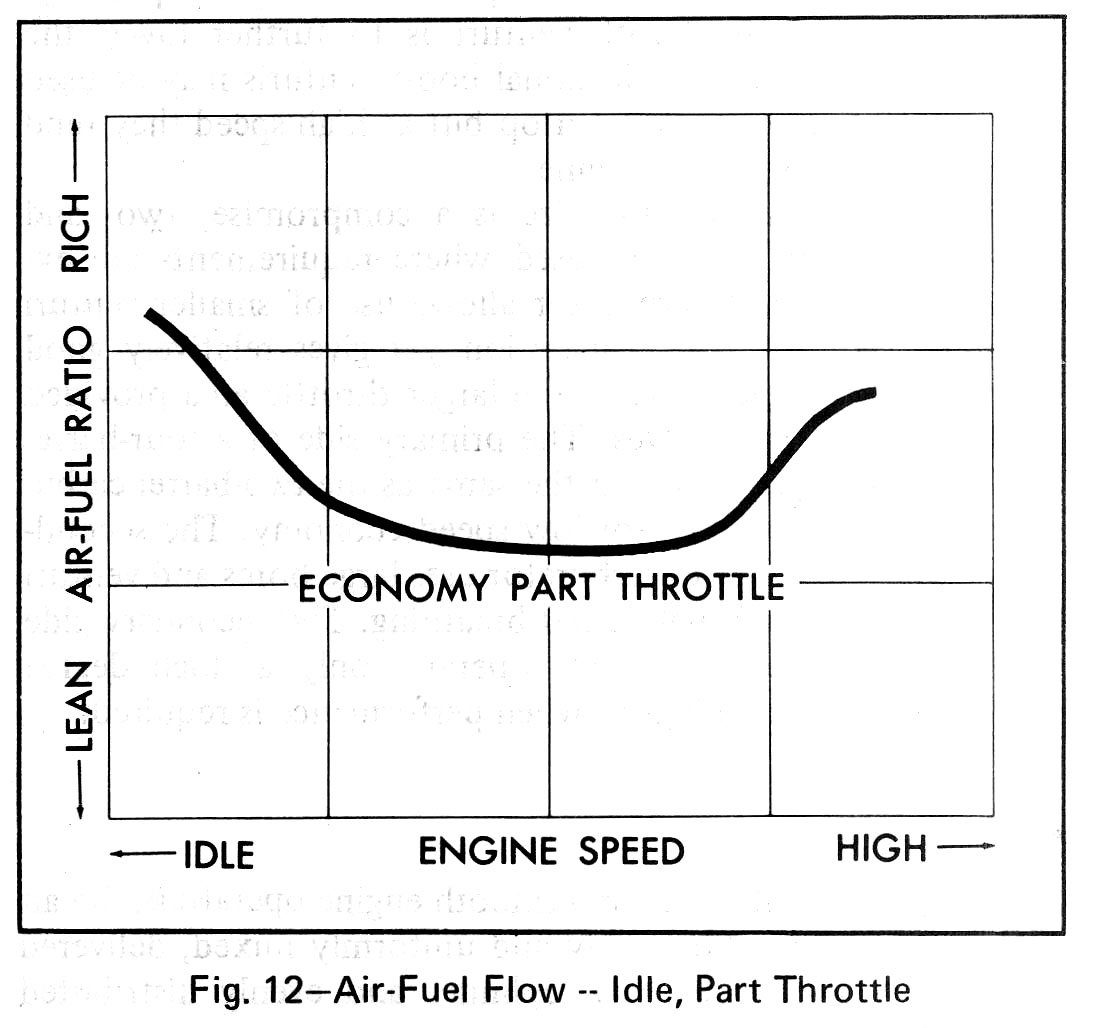

Similarly, the leaner air-fuel ratios for maximum economy at part throttle (Fig. 12) are found to be essentially equal throughout most of the operating range. Again, enrichment is necessary at low speeds and during idling; for the latter, the air-fuel ratio usually falls in the range from 11-to-1 to 12.5-to-1. Richer mixtures are also used at high operating speeds and loads, where more power is required.

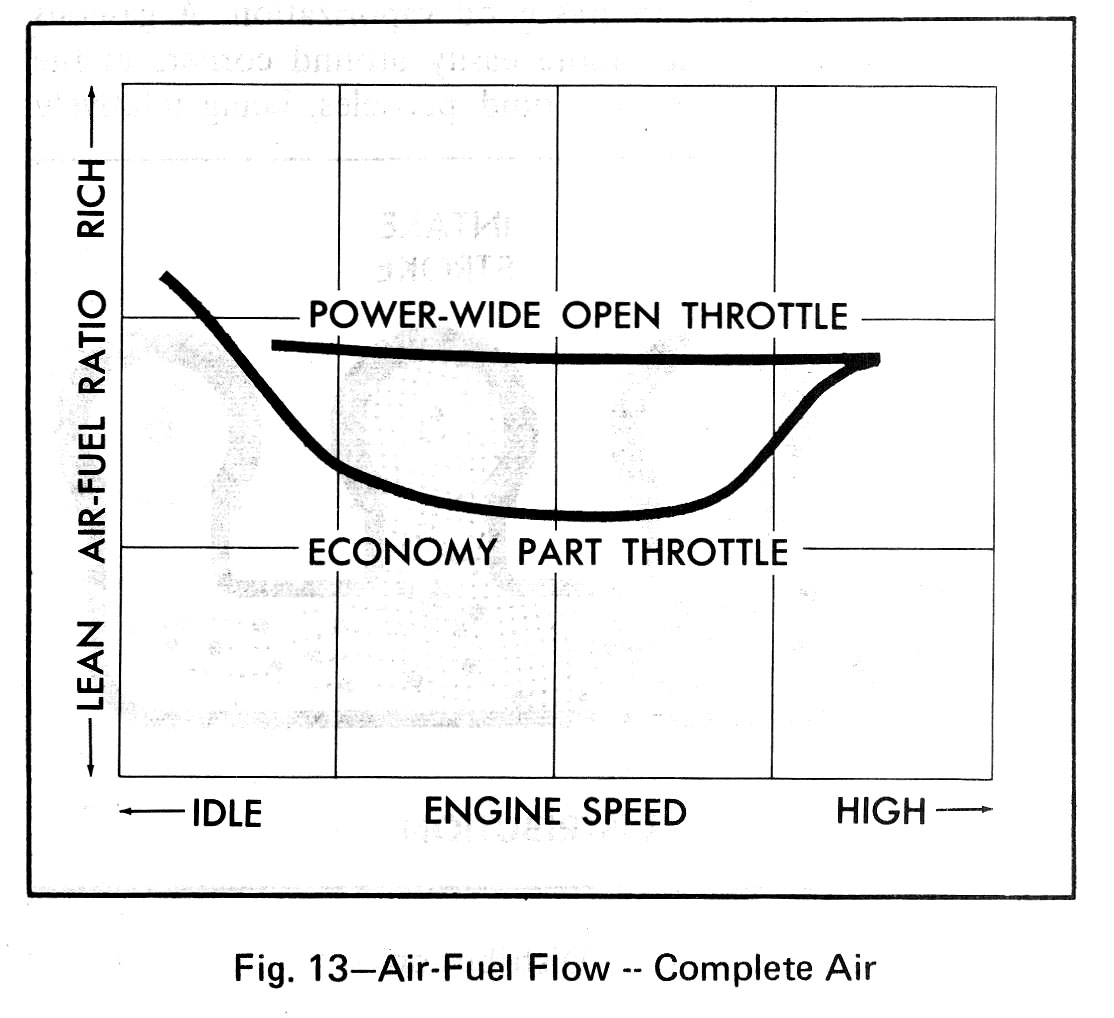

It is usually desirable to operate the engine so that the best fuel mileage can be secured during normal cruising, while maximum power should be available when the throttle is opened for acceleration or top speed (Fig. 13).

Through this point, we have covered the engine's general requirements insofar as the need for both a vaporized mixture and the proportions, or ratio, of the air-fuel vapor for efficient combustion. This leaves only one question which needs clarification before we end this discussion of air-fuel requirements, that is, "Why are richer fuel mixtures needed for cold starts?"

Cold Starts

Recall for a moment that the cigarette lighter could be ignited easily indoors, but after exposure to colder air, the lighter failed to light. It was concluded that the lighter failed to light because there was too little fuel vapor or actually the air-fuel ratio was too lean to burn.

Preheating to increase fuel vaporization to correct the air-fuel ratio is the answer in the case of the cigarette lighter but this would be impractical from a time and cost standpoint for automotive use. We are all aware that a choke is used on carburetors to restrict the air flow and thereby enrich the fuel mixture. Because of this, many assume that a richer mixture is actually burned during cold engine operation but this is definitely not the case.

Although the air-fuel ratio may vary fuel is always burned at a 15:1 ratio. While this may seem contrary to actual conditions, the key is the term "vaporize." Since only vaporized fuel burns and the vaporization rate is sharply reduced at lower temperatures, a rich fuel charge must be admitted so that the total resultant fuel vapor reaching the cylinders will be rich enough to create a combustible mixture. The extra fuel (that which did not vaporize) is minimized, or in some engines is discharged from the port unburned as waste during the exhaust cycle and burned in the exhaust system. While this represents a considerable waste of fuel, it is necessary to provide combustible fuel mixtures until the engine is warmed up. While the discussion of engine air-fuel requirements has been brief, the following points should be remembered: Only vaporized gasoline will burn

Air-Fuel ratios are referenced in terms of weight.

Vaporization rates reduce as temperature declines.

Gasoline always burns at a 15-to-1 ratio; extra fuel is not burned but lost as waste.